08-07

08-07

The level of accuracy that modern plate rolling machines can achieve

08-07

The load-bearing capacity of the three-roller plate bending machine determines the maximum thickness that can be rolled

08-07

Advantages of single-sided radial clamping of plate bending machine

08-07

The daily maintenance and repair work of the rolling machine should not be underestimated!

08-07

What problems should be paid attention to when rolling according to the rules of the rolling machine

08-07

The design and development density of my country's plate rolling machine needs to be improved

08-07

The purchase of a three-roller bending machine must have a certain recognition ability

08-07

The quality of purchased plate rolling machine products should be much higher than the price

08-07

The Development Goal of the Rolling Machine Equipment Manufacturing Industry in the 13th Five-Year Period

Previous page

1

2

Next page

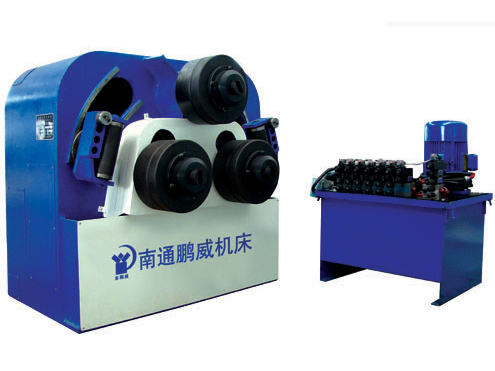

Nantong Pengwei Machine Tool Co., Ltd

Service Hotline:

Add:

Eastern Suburb of Libao Town, Haian County,

Jiangsu Province, China

86-15806274999

86-15806274999

Feedback

Feedback