What problems should be paid attention to when rolling according to the rules of the rolling machine

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2020-08-07

- Views:3

(Summary description)1. According to the rules of the machine lubrication hint, add oil to each oil cup lubrication and manual lubrication points as required.

What problems should be paid attention to when rolling according to the rules of the rolling machine

(Summary description)1. According to the rules of the machine lubrication hint, add oil to each oil cup lubrication and manual lubrication points as required.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2020-08-07

- Views:3

1. According to the rules of the machine lubrication hint, add oil to each oil cup lubrication and manual lubrication points as required.

2. Roll the plate according to the parameters of the plate rolling machine. The thickness of the plate is 20mm, the maximum length is 2500mm, and the yield limit of the plate material is less than 250Mpa.

3. After the power is turned on, carry out the movement of the lower roller in both positive and negative directions and the lifting movement of the upper roller, and check whether there is abnormal jamming of each movement.

4. Operate strictly in accordance with the processing procedures and operating methods of the plate rolling. When the upper roller is raised to the limit position, pay great attention to the safe operation of the equipment.

5. After the main drive is stopped, the upper roller can be raised and lowered, the overturned bearing can be reset and the upper roller can be tilted.

6. During operation, if there is any abnormal appearance such as irregular noise, impact, etc., it should be shut down immediately for inspection.

7. All personnel must reconcile each other during the operation, follow the instructions of the person in charge of the coil, and stop the machine from starting without a password.

8. When carrying out the rolling operation, be very careful that the hand is pressed by the steel plate and is rolled together with the steel plate.

9. When lifting the steel plate or drum with a crane, be careful not to collide with the machine.

After the coil is finished, the place is cleaned as much as possible after the work is completed, and the equipment is maintained and maintained, and the power is turned off in time.

Scan the QR code to read on your phone

Recommended news

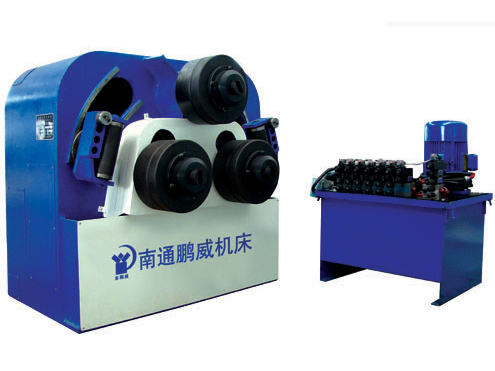

Nantong Pengwei Machine Tool Co., Ltd

Service Hotline:

Add:

Eastern Suburb of Libao Town, Haian County,

Jiangsu Province, China

86-15806274999

86-15806274999

Feedback

Feedback